I think Vitamix blenders are the best on the market, so when I decided to investigate vacuum blending, I rigged up a Vitamix vacuum blender container. The first thing you need for a vacuum blender is an air-tight container. Unfortunately the classic Vitamix lids do not form an air-tight seal. Initially I thought I could just seal the hole in the middle of the lid, but it turns out that the edge of the lid that seals against the container does not hold up to vacuum.

I think Vitamix blenders are the best on the market, so when I decided to investigate vacuum blending, I rigged up a Vitamix vacuum blender container. The first thing you need for a vacuum blender is an air-tight container. Unfortunately the classic Vitamix lids do not form an air-tight seal. Initially I thought I could just seal the hole in the middle of the lid, but it turns out that the edge of the lid that seals against the container does not hold up to vacuum.

Contents

Introduction

If you decide to make your own, keep in mind that doing so voids the warranty. I haven’t had any problems with my modifications, but proceed at your own risk.

Interestingly, the new Ascent Series Vitamix lids have an airtight gasket, but I wanted to be able to blend smaller amounts for my testing. Vitamix has plans to release a smaller Ascent container, but I don’t know when it will come out [for updated info, see addendum at end]. I decided to make a sealed lid for a 32-oz classic Vitamix container.

The first challenge with sealing a Vitamix container is that the top is not flat, so you can’t just use a flat gasket. However, we are fortunate on a separate matter: directly below the pour spout the inside of the container is a perfect circle. So I decided to make a lid to seal against that circle. Below that circle, the walls transition to a square, so that transition point prevents the lid from going too far into the container.

Here’s the overview: I cut a piece of acrylic for the lid, and then I cut a slit in silicone tubing and put it around the acrylic to form a gasket.

I used a laser cutter to cut the acrylic. You might be surprised to find a laser cutter that you can use near you. Search for fab lab, makerspace, or hackerspace. I’ve also heard that some libraries have them. You could also use a saw.

Parts list for lid

Update: I now prefer a simple one-way valve on the lid. See my new Vitamix Vacuum Blending post for more details.

(Note that Amazon prices jump around, so some of these might no longer be the best deal. Also, these are affiliate links, so I get a little commission if you order via them, at no extra cost to you.)

Total cost is about $100 to $170, depending on how many of the tools you already have, and if you opt for the optional vacuum gauge and valves.

1/4″ clear acrylic sheet (if there’s a TAP plastics or similar store near you, you can save money by buying a scrap piece from them. Or, if you find a place with a laser cutter, they may have scraps for free.)

1/4″ID, 1/2″OD Silicone Tubing (for gasket)

Stainless Steel 1/4″ Barb Fitting

1/4″ ID vinyl tubing (for vacuum lines)

Tools you’ll need:

utility knife with fresh blade

7″ hose clamp (cheaper at local hardware store or home depot)

Making the lid

For the 32-oz Vitamix container I cut a 4.9″ disk from the acrylic, with a 7/16″ hole for the tap. Then I rounded the top and bottom of the outer edge of the disk with the file. I filed it so that the corners have about a 1/16″ radius, evenly all around the disk.

I cut a piece of the silicone tubing to go around the disk, and cut a single slit along its length. Getting just the right length is tricky, so I used the first piece as a rough draft, and then adjusted the length to get the second piece just right. You can also check that the lid with silicone around it will go onto the container. It has to slide in a bit, so I rubbed it with a little cooking oil, to allow it to slide in. If it’s too tight, you can file off a bit more of the acrylic.

When you cut the silicone you want the cut to be straight and perpendicular to the tubing length. I found it hard to get a nice cut when trimming off small amounts, so that’s why I used the “rough draft” piece for sizing help. The silicone is flexible enough that there is a bit of leeway.

Try to keep the silicone tubing clean.

I put the correct length piece of slit silicone tubing around the disk. I used masking tape to tape one end in place and applied silicone sealant to the flat end of the tubing. Then I put the other end of the tubing flush against the first end, and taped it in place as well. I also put a piece of masking tape over the joining area. Then I used a hose clamp to hold everything in place while the silicone cured. The hose clamp goes around the outside of the silicone tubing on the disk. The hose clamp does not have to be tightened super-tight, just enough to keep the ends flush. I put masking tape on the inside of the hose clamp that would contact the sealant. I let it cure for 24 hours, and then removed the hose clamp.

Then I cut threads in the middle of the lid for the barb fitting using the tap and crescent wrench. I wrapped the fitting in PTFE tape, and screwed it in.

I also ended up sealing the interface between the slit silicone tubing and the disk with silicone because sometimes blending liquid splashed up, and it was able to get between the lid and the inside of the silicone tubing gasket.

Vacuum Pumps

There are manual vacuum pumps, but I figured it would be more convenient to have an electric one. The first ones I found are the big ones with a handle that people use for HVAC work. However, I think those are overkill for this application, and I also learned that they exhaust a fine mist of oil particles. That’s fine if you’re in a work site or garage, but I figured it would be too messy for the kitchen.

Then I came across these small 12V electric vacuum pumps on Amazon. I decided to get two to try running them in series. I got the cheapest, and the second cheapest, and they appear to be identical aside from the label. According to my vacuum gauge, each one pulls 21 inHg, and together they pull 27 inHg. The lid is able to hold that vacuum without leaking for the minute or two it takes to blend. (I didn’t do long-term leak tests because they’re not relevant to vacuum blending.)

I haven’t done comparative testing to see how much extra benefit the second pump gets you. It’s the difference between removing 70% of the air and removing 90% of the air. I figured if I’m taking the time to do this, it’s worth going for the double pump setup.

A note about units

The units for measuring vacuum can be a bit confusing. There are many different units, and to make it worse, sometimes people count down from atmospheric pressure, and sometimes they count up from absolute vacuum. In principle when counting down below atmospheric there should be a negative sign, but it usually gets dropped. In the US, the most common unit for this type of vacuum seem to be inches of mercury (inHg) below atmospheric. If you want to convert units, I recommend Google’s unit conversion tool. You can google “X unitA in unitB” (e.g. “27 inHg in mbar”). Just note that it doesn’t work with negative signs.

If you use those 12V vacuum pumps you’ll need a 12V power supply. I was able to find an old one around the house, but if you don’t have one, you can get one on Amazon. I measured the 12V vacuum pumps use 650mA at vacuum. (The cheaper of the pumps, which is the one I recommend, has some false information in its description stating that it uses up to 96W—that is just wrong.) I’d round up and use a minimum of 1A per pump, maybe 1.5A to be on the safe side. I’m running the two pumps on a 3A power supply.

If you go this route, you’ll also need a plug, wire, solder, and soldering iron to connect it up. If you found a place with a laser cutter, they may also have these materials available.

Alternatively, you could get a pre-wired pump for a vacuum sealer like this one (or if you already have a vacuum sealer, some of them have an accessory hose). You could also try a hand-powered pump; here are instructions for converting a bike pump.

Vacuum Gauge

A vacuum gauge is optional, but I think it’s nice to have, since you can use it to check that you don’t have leaks, and also to tell what kind of vacuum you’re pulling. You also don’t necessarily need valves, but I decided to get them to make it easier to remove the lid. If you don’t get valves, you’ll remove the vinyl tubing from the barb on the lid each time you open it.

Barstock Cross, 1/4″ x 1/4″ x 1/4″ x 1/4″ NPT Female

2x Mini Ball Valve, Lever, 1/4″ NPT Male x NPT Female

2x Brass Hose Fitting, Adapter, 1/4″ Barb x 1/4″ NPT Male

Pump and Gauge Assembly

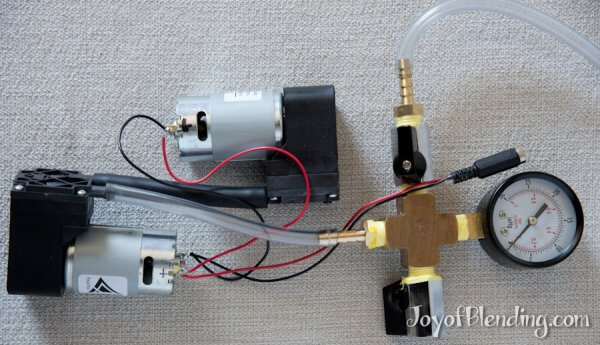

There are various configurations that would require other fittings, but I think the one I have with the cross, valves, and gauge at the pump end of the tube works pretty well.

Here’s what the pumps and gauge look like all hooked up:

I currently put the pumps in a small cardboard box, but I may make a nicer box with an on-off switch, possibly from laser-cut acrylic.

I currently put the pumps in a small cardboard box, but I may make a nicer box with an on-off switch, possibly from laser-cut acrylic.

Ascent Containers Addendum

Update: I found that the Ascent lids can fully seal if you add an o-ring. See my new Vitamix Vacuum Blending post for more details.

Update: I found that the Ascent lids can fully seal if you add an o-ring. See my new Vitamix Vacuum Blending post for more details.

The new Vitamix Ascent series comes with containers that have a new type of lid, which seals better than the old Vitamix lids. The Ascent lids also have a rigid flat surface on their top. I was thinking that it should be possible to use a flat gasket to seal a piece of acrylic on the top (as shown in the photo to the right).

It’s easier to make the flat gasket than the cut tubing gasket (as I did for the old 32-oz container), because you don’t have to file the corner of the acrylic, and exact dimensions don’t matter.

I found a silicone sheet, and cut a gasket from it. I put the cut gasket on the Ascent lid, and put a piece of acrylic on top of it. I applied vacuum, and found mixed results. I tested three 64-oz containers and two 48-oz containers. Of the 64-oz containers, one works perfectly (it goes to the 27 inHg that my pumps are capable of), one doesn’t work at all, and one is in between. The in between one sometimes starts slowly leaking when it gets to 16 inHg, and sometimes it doesn’t leak. With the slow leak, my pumps can get it to 20 inHg by running continuously. A bigger pump would be able to get it a bit lower. 16 inHg is enough to notice the benefits of vacuum blending, so it’s usable.

I swapped the lids around, and whether they leak or not depends on the lid, not the container. I presume it has to do with the state of the Vitamix-stock gasket, but I did not notice obvious differences when looking at them.

Neither of the 48-oz containers hold any vacuum. Upon close inspection of the 48-oz lids in place, it looks like they are just not designed to fit as snugly as the 64-oz lids. In principle you could try to augment the stock gasket that seals against the container, but it seems like that would be a pain.

In summary, I think this approach is viable for 64-oz Ascent containers, but you have to be ready to try a different lid if your first one doesn’t work. I believe Vitamix will sell you a replacement lid for ~$10 if you call them, and I think you can get replacement gaskets for even less.

One side note about using the 64-oz containers is that they take about twice as long as the 32-oz containers to pump down. (Pumping time is proportional to the volume of air in the container.) So if I were using 64-oz containers regularly for vacuum blending, I would probably want either additional pumps or a bigger pump.

Great article and idea, thanks!

Do you know if the Ascent Series caraffes are actually air tight? When I examined one at Williams Sonoma, the seal inside the vent seemed that it might possibly be airtight, but the one around the perimeter, although a very nice looking splashy liquid, looks to me like it would not hold pressure.

I did a very brief test on the Ascent container, and the lid’s perimeter gasket seemed to hold vacuum. However, to be fully confident I’ll need to do further testing. I used the lid I made for the 32-oz container, and it mostly sealed, but it started leaking on the Ascent container at around -16 in Hg. The leak was because of slightly raised writing on the top of the ascent lid, and the gasket for the 32-oz was too narrow to perfectly seal it. Once I get a flat gasket I can do better vacuum testing of the Ascent container, but I think it will seal well enough.

I tested some flat gaskets on Ascent lids, with mixed results. I added a section describing them.

So with the ascent series there’s no need for a vacuum ?

My point about the Ascent series is that the Ascent lid should make it easier to make a sealed vacuum lid for those containers. If you want to vacuum blend, you’d still need vacuum though.

For the 64-oz Vitamix container would you cut a 5.5″ disk from the acrylic? Thanks.

There are two kinds of 64-oz containers: tall/narrow, and short/wide. With that measurement, I’m guessing you have a tall/narrow one. That sounds about right. I measured that part of the container opening at 5.1″ for the 32-oz and 5.75″ for the tall 64-oz. I didn’t file down the corners of the disk precisely, so my measurements aren’t that precise. I just filed down the corners until the lid could slide in with the gasket (you can test the fit before gluing the gasket).

One other thing—upon closer inspection of the tall/narrow 64-oz container, it looks like it might be a slightly harder to get a good seal, because the pour spout goes closer to the area you’d be trying to seal. It looks like it may still be possible, but I don’t know for sure if this design will work on that container.

Yes, I have the the tall/narrow 64-oz. For the 32-oz in your post you said you cut a 4.9″ disk from the acrylic, but you measured the opening to be 5.1″. Is the .2″ difference to account for the gasket, ie if the opening for the 64-oz is 5.75″, should I cut a 5.55″ disk from the acrylic? Thanks again.

Correct. I just hesitated to specify down to less than 0.1″ because of how imprecise my filing job was.

I’m curious if this type of lid will work on that container, so please report back with how yours goes.

Definitely. Thanks for your help.

I made one following the directions above — exact parts and all. My first lid leaked. There were two possible mistakes in the construction. I filled the tube with silicone glue and clamped it very tightly around the circumference with a hose clamp while gluing. For my second try, the tube was not pulled extra tight and only glued at the edges touching the lid disk. It turned out so snug in the pitcher that when, in my haste to try it out, I neglected to oil the pitcher, I had a hard time getting it out. Duly spreading oil inside the pitcher mouth and on the lid tubing, first just empty to test the vacuum and then orange-apple-strawberry, it all worked perfectly. AND IT WAS DELICIOUS!

I’m not sure, but I think that having a little give in the silicone tubing allows it to flex and form itself into shape.

Wow! Vacuum technology with my own hands!

Would anyone fancy making one of these for me? Would pay you of course 🙂

Howdy,

I tried this many years ago but my problem was the vacuum pump sucked air through the bottom bearing. Are the new bearings good enough that this doesn’t happen? For reference, I was using a very strong vacuum pump. My application was to prevent air from being introduced during the blending of hydrocolloid mixtures.

I was wondering if that would be a problem, so I did some tests applying vacuum to the container with just water in it. I watched to see if any air bubbles came in from the bearings, and I never saw any. However, my pumps only went to ~-27 mmHg, so it’s possible that an ultra-high vacuum would cause them to leak.

Hi Adam,

do you still bother vacuuming before you blend now that you have it all set up?

I have the new ascent jug and am thinking about doing it.. do you have more photos of how you have it set up?

I vacuum sometimes, but I still haven’t gotten around to making a nice box and power switch for my pumps, so most of the time I don’t bother. Also, I drink my smoothies right away, so that reduces the difference that I would get with vacuum blending.

I am noticing that more and more blenders have a taller lid edge hanging down from the top surface, I wonder if these would work better has anyone tried any ? Thank you

soo 15 hg yields a 50% vacuum or air expansion of about 2, so you cut your o2 by only half. 20 hg does about 80%, or air expansion of about 5 thereby cutting o2 by about 85%. This does 20hg, best case, which still leaves about 15% air in there, ie- 2.5% of the total volume is still o2 (16%/6). Has anyone tried simply lowering the lid until there’s no room for air?

I don’t know why you wrote, “This does 20hg, best case,” when I reported getting to 27 inHg of vacuum. Also, I believe your math is wrong.

That said, lowering the lid is an interesting idea that might provide some reduction in oxidation. However, I’m pretty sure it wouldn’t do as much as applying a vacuum, and I’m not sure how you would do it. Before Tribest launched their vacuum blender they released a silicone suction lid which sort of does what you’re describing, though I’m pretty sure it is less effective than having a sealed lid with a decent vacuum pump.

In laboratories, material is sometimes blended under an inert gas. There are many very inexpensive gases to choose from. Some foods are nitrogen packed. Blending under inert gas does not eliminate bubbles, of course, but it does eliminate oxidation, perhaps even better than partial vacuum.

I considered trying to purge with inert gas before I heard of vacuum blending. While it’s true that nitrogen gas is cheap, it’s relatively inconvenient to set it up in the home kitchen. A tank plus regulator isn’t so cheap, it’s pretty bulky, and you need to find a source to fill your tank with food-grade nitrogen. As a fringe enthusiast I could set it up, but I don’t think most people would want to.

And the vacuum works surprisingly well. If someone wants to go beyond the setup I described here, I think the next step would be a more powerful vacuum pump (maybe a rotary vane pump).

If you want to experiment with inert gas, there are some relatively cheap non-refillable canisters sold for wine preservation. However, it seems like you would go through too many canisters if you were using them regularly.